WE ARE AN ATLAS COPCO PREMIER DISTRIBUTOR

Atlas Copco is a recognised industry leader, whose air compressor products provide robust solutions that are innovative, reliable and energy efficient.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorised as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site....

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

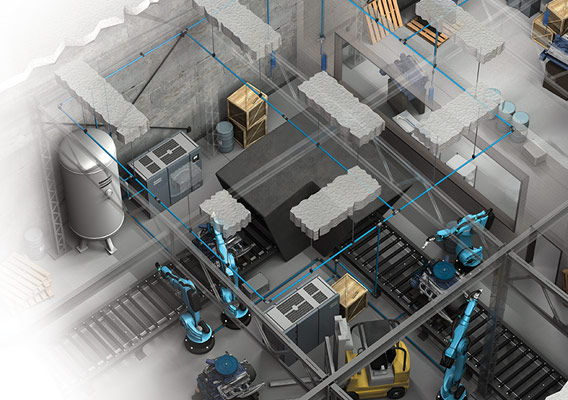

ACL Engineering has years of experience in assessing and evaluating air compressor system requirements across a broad range of businesses and services.

Whether your business involves manufacturing, production lines, conveyor systems, power tool operation, food production and brewing, medical laboratories, water treatment or metal fabrication, to name but a few – we are the experts when it comes to specifying a new system.

You’ll be visited by one of our account managers who will discuss your business requirements and aims. We assess any particular needs, or restrictions, including power output, energy efficiency, H&S, timescale and budget.

We will also review the location and space to fully understand the context and end-use of the compressor system.

This is a collaborative process and seeks to work with you and your team to design a bespoke system for your precise needs. We look to proactively manage energy usage, whilst delivering the necessary power to your processes.

Existing system upgrades and optimisation

If you have an existing system that requires an upgrade or are looking for improvements in running costs and efficiency, then we can rapidly implement a detailed audit, analysing performance data across your air compressor system.

The results provide insights into ways to improve and supplement existing technology and equipment to extend the life of your system and deliver better returns.

TALK TO OUR TEAM ABOUT YOUR AIR COMPRESSOR DESIGN & SPECIFICATION REQUIREMENTS