Electronics

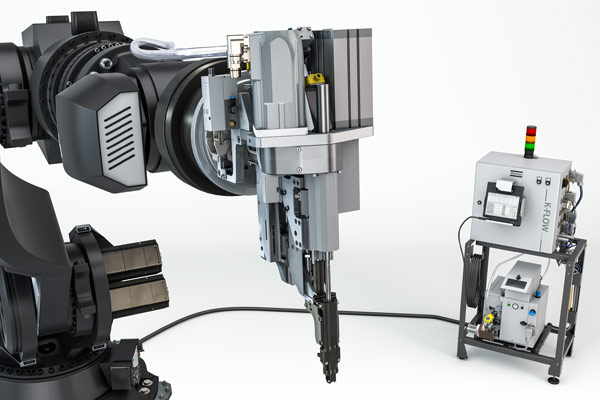

Most electronic circuits are very delicate and susceptible to contamination. At ACL Engineering we recognise the need for efficiency, low impact and cleanliness in electronics manufacturing, to preserve the integrity and performance of the goods produced.

Air Compressors in electronics manufacturing

Most electronics and semiconductor manufacturers prefer compressed air for electronic applications because it has high energy conversion efficiency while remaining low impact.

Certified oil-free air in your clean room

Oil-free compressors eliminate the risk of potential contamination found with oil-injected systems. They deliver a totally clean, consistent air supply which helps maintain high purity, standards and the level of quality control essential in this industry.

Uses of compressed air include:

- Pick and place systems – e.g. the pneumatic conveyance of components or operation of sensitive valves.

- Printed circuit board cleaning – PCBs are delicate and sensitive by nature. Compressed air provides low impact and low abrasion to clear dust and particles without damage.

- Desoldering – the removal of solder and components from circuit boards

- Air knives – high performance drying, blow-off and cleaning in production

- Pressurising cables – to prevent water ingress into cables

Speak to our team about air compressor systems in electronics manufacturing